Corrosion monitoring technique!

Principle

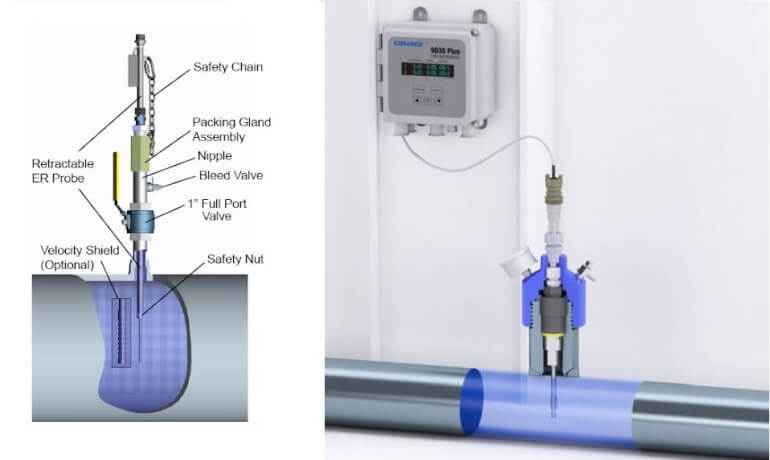

Corrosion monitoring method, namely the measurement of pressure vessel shell and pressure element metal corrosion resistance changes. If the corrosion is essentially uniform, the change in resistance is proportional to the increase in corrosion. From each reading, we can calculate the total amount of corrosion over time. This also allows you to calculate the corrosion rate. If we choose components with sufficient sensitivity, we allow the corrosion rate to change relatively quickly. If the corrosion rate change parameter is very important, we can choose other more appropriate methods.

Advantage

The advantage of this method is that corrosion in liquid or gas phases can be measured. In addition, unlike the polarization resistance method, the liquid phase must be an electrolyte. Disadvantages: Measurements are not easily interpreted unless the corrosion is uniform. Therefore, the method is not suitable for pitting, stress corrosion cracking or other local corrosion damage. In addition, it has the same weaknesses as techniques that typically insert test elements into production Settings as probes. The probe behavior is unlikely to be the same as the production unit itself.