EMT Polyurethane 3 Cups Pipeline Pig

- EMT

- Shenyang, China

- 15 days

- 200 sets/month

The EMT Polyurethane Pipeline Pigging 3 cups pig is manufactured using polyurethane casting, providing several benefits for pipeline cleaning operations. By utilizing polyurethane throughout the pig's construction, it combines the advantages of effective sealing and cleaning capabilities inherent in cup pipeline pigs while also enhancing its ability to pass through the pipeline.

The polyurethane casting creates a seamless and durable structure for the pig, ensuring reliable sealing and cleaning performance. The improved passing ability of the pig enables it to navigate through the pipeline with ease, even when encountering changes in the conveying medium.

The cup pipeline pig is specifically designed to excel in various aspects. It possesses strong passing ability, allowing it to smoothly travel through the pipeline without causing disruptions to the flow. Its exceptional sealing performance ensures that it effectively maintains the integrity of the pipeline by preventing leaks or loss of product. Additionally, the pig's cleaning effect is highly regarded, effectively removing debris and contaminants from the pipeline, resulting in improved operational efficiency.

Due to its impressive capabilities, the cup pipeline pig has gained widespread use in long-distance pipeline cleaning applications. It is particularly well-suited for heavy cleaning tasks, where thorough removal of deposits or accumulated materials is required. The pig's design and composition make it a reliable tool for maintaining and optimizing pipelines in various industries.

Pipeline Pig Description

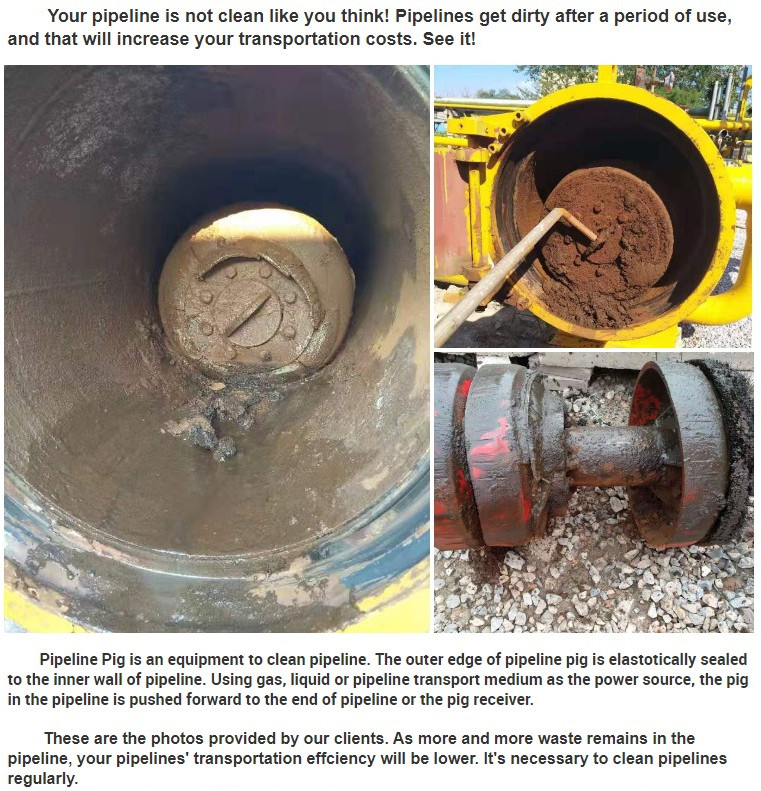

Pipeline pigs are commonly used in the oil and gas industry for pipeline cleaning and maintenance.

The EMT Polyurethane Pipeline Pigging 3 cups pig is a specific type of pipeline pig designed for

efficient and effective cleaning operations.

The main body of the 3 cups pig is constructed using a sturdy steel framework. This steel framework

provides the necessary strength and durability required to withstand the harsh conditions often

encountered in pipeline environments. It ensures that the pig can effectively traverse the pipeline

while maintaining its structural integrity.

The pig is equipped with 2-4 sealed cups or a steel brush, which are essential components for its

cleaning functionality. These cups or brush are strategically positioned on the pig's body to create

a sealing effect against the pipeline walls. When the pig is inserted into the pipeline and propelled

by the flow of fluid or through mechanical means, the cups or brush come into contact with the

pipeline walls, effectively removing debris, sediment, and other contaminants. This cleaning action

helps to maintain the pipeline's efficiency and integrity.

The cup material used in the construction of the 3 cups pig can vary based on specific requirements.

Common cup materials include Polyurethane, Viton, Neoprene, Nitrile butadiene, and others. Each

material offers distinct properties such as flexibility, resistance to abrasion, chemical compatibility,

and temperature tolerance. The choice of cup material depends on factors such as the nature of the

pipeline, the type of contaminants to be removed, and the operating conditions.

The EMT Polyurethane Pipeline Pigging 3 cups pig has a proven track record of long-term usage in the

Daqing oil field and the Liaohe oil field. Its stable performance and reliable quality have garnered

positive feedback from customers in these fields. The pig's ability to effectively clean pipelines and its

durability in demanding environments have made it a trusted choice for pipeline maintenance operations.

Overall, the EMT Polyurethane Pipeline Pigging 3 cups pig with its steel framework, sealed cups or steel

brush, and various cup material options offers a robust solution for pipeline cleaning. Its reliable performance

and positive customer feedback make it a valuable tool in ensuring pipeline integrity and efficiency in the

oil and gas industry

Pipeline Pig Test Report

Report No.TD-20I90117-045N-2 CX99JL03

SUMMARY OF TEST RESULTS | ||||

NO. | TEST PROJECT | UNITS | TEST RESULT | TEST METHOD |

1 | Shore hardness | Shore A | 83 | GB/T531.1-2008 |

2 | DIN abrasion | mm3 | 21 | GB/T53516-1987 |

3 | Akron abrasion | crn3 | 0.0518 | GB/T1689-1998 |

4 | 100%stress at definite elongation | MPa | 3.41 | GB/T528-2009 |

5 | 300%stress at definite elongation | MPa | 5.74 | GB/T528-2009 |

6 | Tensile strength | MPa | 51.2 | GB/T528-2009 |

7 | Elongation at break | % | 1263 | GB/T528-2009 |

8 | Tear strength (right Angle) | kN/m | 77 | GB/T529-2008 |

9 | Resilience rate | % | 34 | GB/T168-2009 |

5.Pipeline Pig Cup Type Usage

(1) Cleaning the new-built pipeline.

(2) Remove rust and clean before coating in the pipeline.

(3) Remove rust and clean before repairing the pipeline.

6. Pipeline Pig Cup Type Minimum Order Quantity(MOQ):1 Piece .

7. Pipeline Pig Cup Type Payment term:T/T or L/C at sight

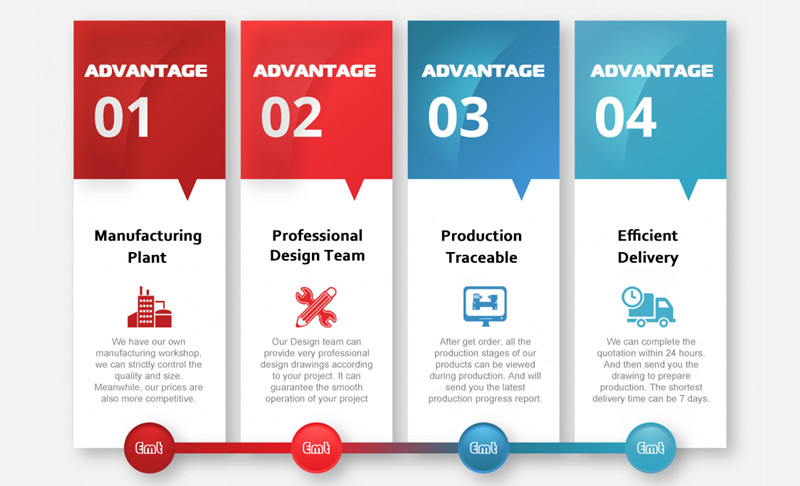

Why Choose Us

Our Services

1. Many kinds of pipe cleaning pig with a different type to meet different requirements.

2. Samples will be offered to attest to the quality and our services.

3. The fastest feedback!

4. The fastest delivery time.

5. 24 hours,7 days online.

Company Information

We Shenyang EMT Pigging Technology Co., Ltd. was founded in 2004 has developed to a science and technology development enterprise that combines science development, product development, production, sales, and service as a whole. The meters, instruments, and equipment developed have been widely used in petroleum, power, chemical, liquor-making, metallurgy, mechanical industries. Our institute has professional R&D, sales, site and after service staff with strong strength of R&D, development, production, and installation.