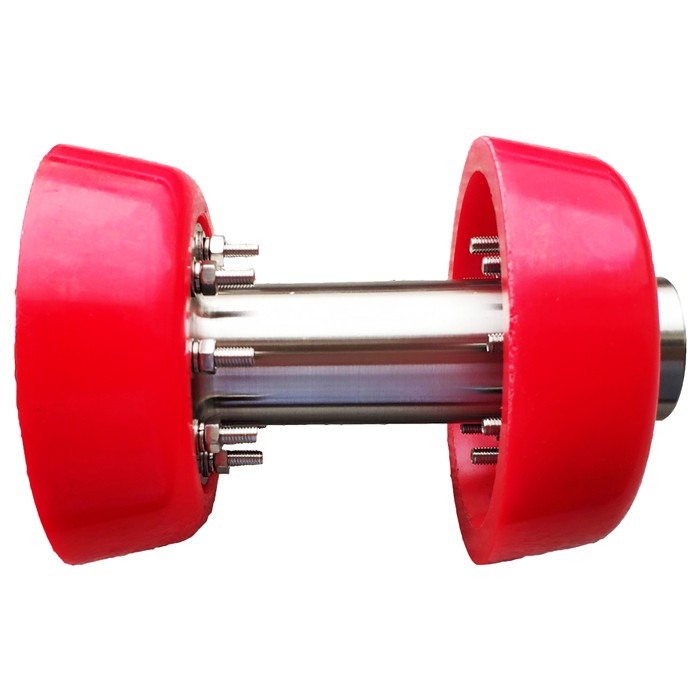

EMT Two Cup Pipeline Pig with Transmitter

- EMT

- Shenyang,China

- Depend On Quantity

- 200 sets/month

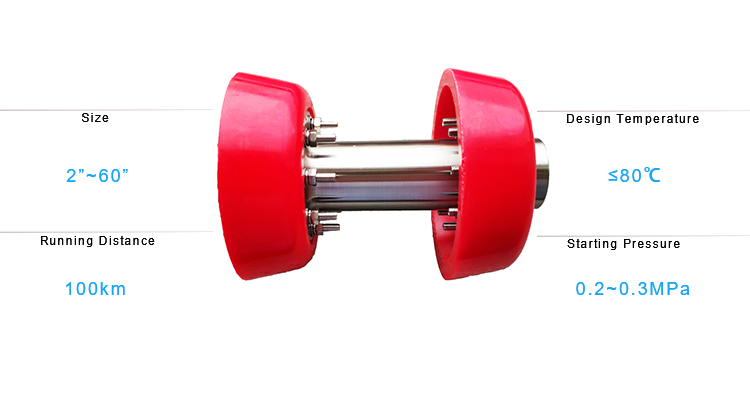

EMT Two Cup Pipeline Pig with Transmitter consists of a stainless steel mandrel body, two polyurethane cups and a transmitter. The position of the transmitter can be located by the receiver, then can determine the location of the pig.

Pipe Pig Description

I. Customization and Accessories

A. Mention of customization options based on user requirements:

The Pipeline Cup Cleaning Pig offers a range of customization options to meet specific user requirements.

This includes customization of the pig's size, shape, and cup or brush configuration. Users can select the

appropriate dimensions and specifications to ensure the pig fits their pipeline system seamlessly, optimizing

its cleaning and maintenance performance.

B. Addition of accessories to the pig, such as steel brushes or transmitters:

To enhance the capabilities of the Pipeline Cup Cleaning Pig, various accessories can be added. For instance,

steel brushes can be attached to the pig to provide more aggressive cleaning action, effectively removing

tough deposits or scale from the pipeline walls. Additionally, transmitters can be incorporated into the design,

allowing real-time tracking and monitoring of the pig's position and progress within the pipeline.

C. Importance of these accessories in meeting specific needs:

The availability of accessories for the Pipeline Cup Cleaning Pig is crucial in meeting specific cleaning and

maintenance needs. Different pipelines may have varying levels of contamination or unique challenges that

demand specialized cleaning approaches. By incorporating accessories like steel brushes or transmitters, the

pig can be customized to address these specific needs, ensuring thorough cleaning, accurate tracking, and

efficient maintenance operations.

II. Applications of the Pipeline Cup Cleaning Pig

A. Routine pipeline cleaning using the mechanical pig:

One of the primary applications of the Pipeline Cup Cleaning Pig is routine pipeline cleaning. The pig's design,

with its sealed cups or steel brushes, allows it to effectively remove debris, sediments, and contaminants from

the pipeline walls as it travels through. Regular cleaning using the pig helps maintain the integrity and efficiency

of the pipeline, preventing blockages, corrosion, and other issues that can hinder operations.

B. Utilization of the pig for pipeline filling and batching processes:

The Pipeline Cup Cleaning Pig also plays a vital role in pipeline filling and batching processes. During these

operations, the pig can be used to ensure proper product displacement, uniform distribution, or separation of

different substances within the pipeline. By precisely controlling the pig's movement and incorporating features

like adjustable cups or brushes, the pig facilitates smooth and efficient filling and batching processes.

C. Significance of the pig in the industrial production process:

The Pipeline Cup Cleaning Pig holds immense importance in the industrial production process, particularly in

sectors relying on pipelines. It ensures the cleanliness and integrity of the pipeline, minimizing the risk of contamination,

product quality issues, and operational disruptions. The pig's reliable performance and adaptability contribute to

uninterrupted production, cost savings, and increased operational efficiency, thus supporting the overall success

of industrial processes.

III. Conclusion

A. Recap of the Pipeline Cup Cleaning Pig's features and capabilities:

The Pipeline Cup Cleaning Pig offers customization options to meet specific user requirements, including the addition

of accessories such as steel brushes or transmitters. Its applications range from routine pipeline cleaning to facilitating

pipeline filling and batching processes.

B. Emphasis on its importance and role in industrial production:

The Pipeline Cup Cleaning Pig serves as a crucial tool in maintaining pipeline integrity, cleanliness, and efficient operation

in various industries. Its ability to address specific needs through customization and the incorporation of accessories ensures

effective cleaning and maintenance, contributing to the overall success of industrial production processes.

C. Potential benefits and value it brings to pipeline maintenance and operations:

By utilizing the Pipeline Cup Cleaning Pig, industries can benefit from reduced downtime, improved product quality, and

extended pipeline lifespan. The pig's reliable performance and adaptability offer cost savings, increased operational

efficiency, and peace of mind for operators, highlighting its value as an essential component of pipeline maintenance

and operations.