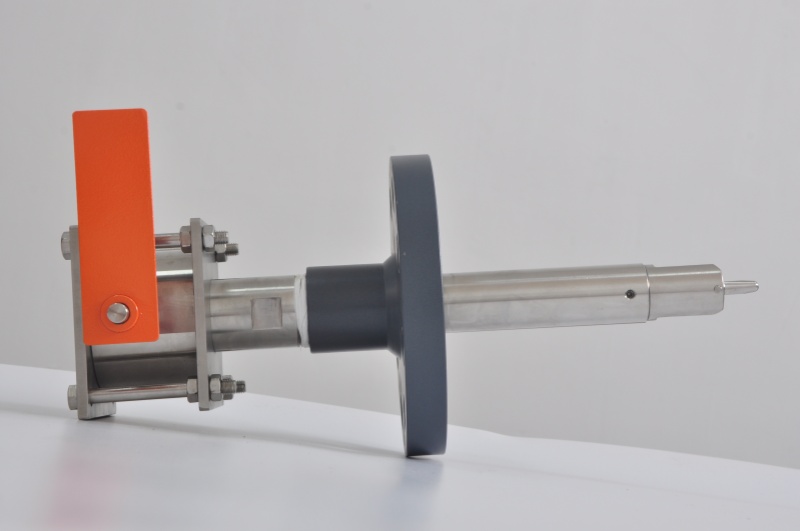

Bidirectional Flange Pig Signaler

- EMT

- Shenyang, China

- 15 days

- 200 sets/month

The Bidirectional Flange Pig Signaler is the necessary equipment in the pipeline pass-through pipe cleaning process.Bidirectional Flange Pig Signaler is fixedly installed above the pipeline to determine whether the pig has passed the test point. Bidirectional Flange Pig Signaler can provide information to the operator through secondary sources such as light, point, sound or special clock to guide the switching process.

Bidirectional Flange Pig Signaler(Pig Indicator)

The Pig Indicator, also known as the Bidirectional Flange Pig Signaler, is utilized to ensure the accurate

tracking of pipeline pigs as they traverse through the pipeline. These signalers are typically installed

at both the pig launching and pig receiving stations, as well as at strategic locations along the pipeline.

Their primary function is to provide reliable confirmation of pig movement in both directions.

Benefits of EMT Pig Signaller(Pig Indicator)

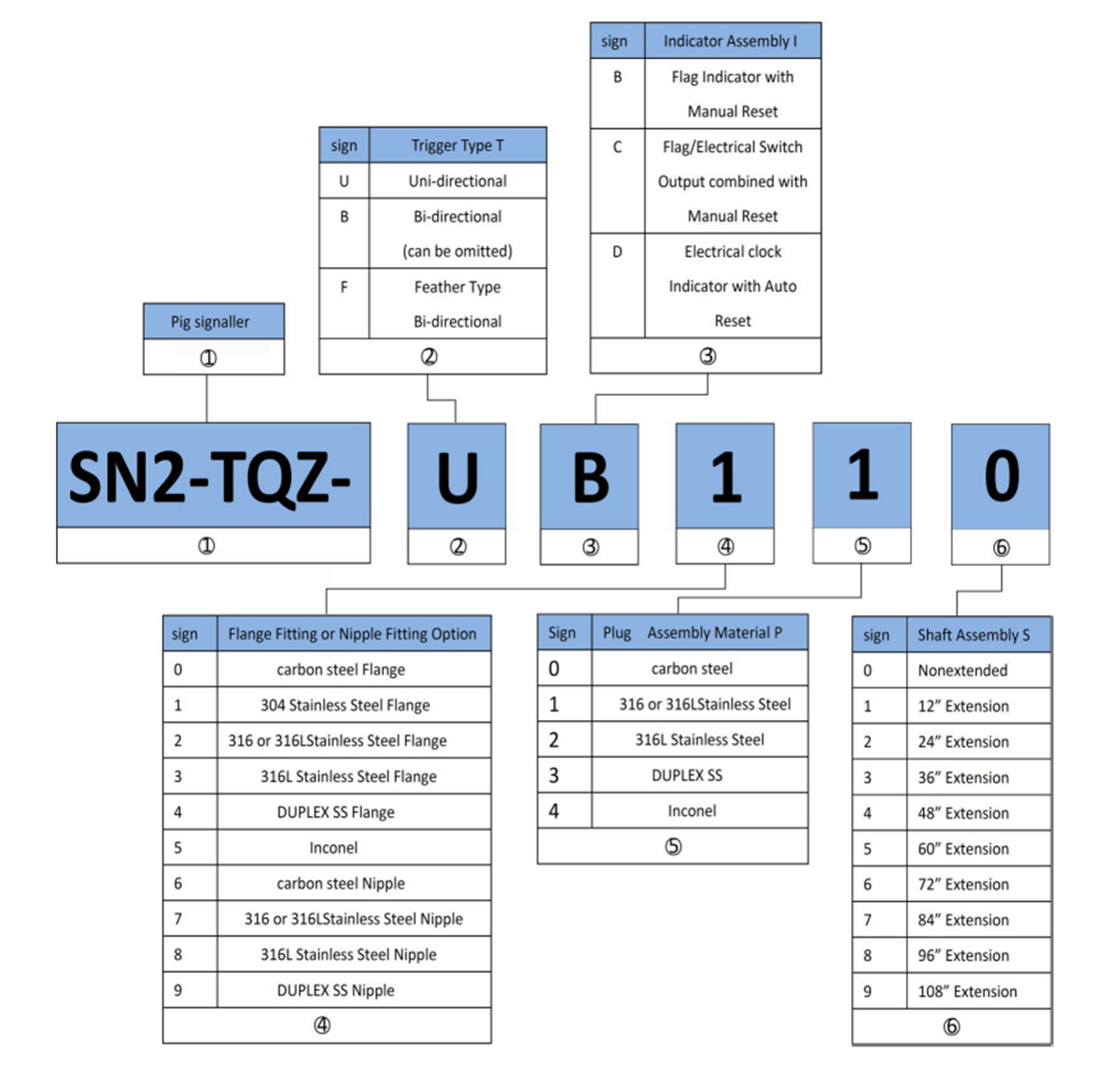

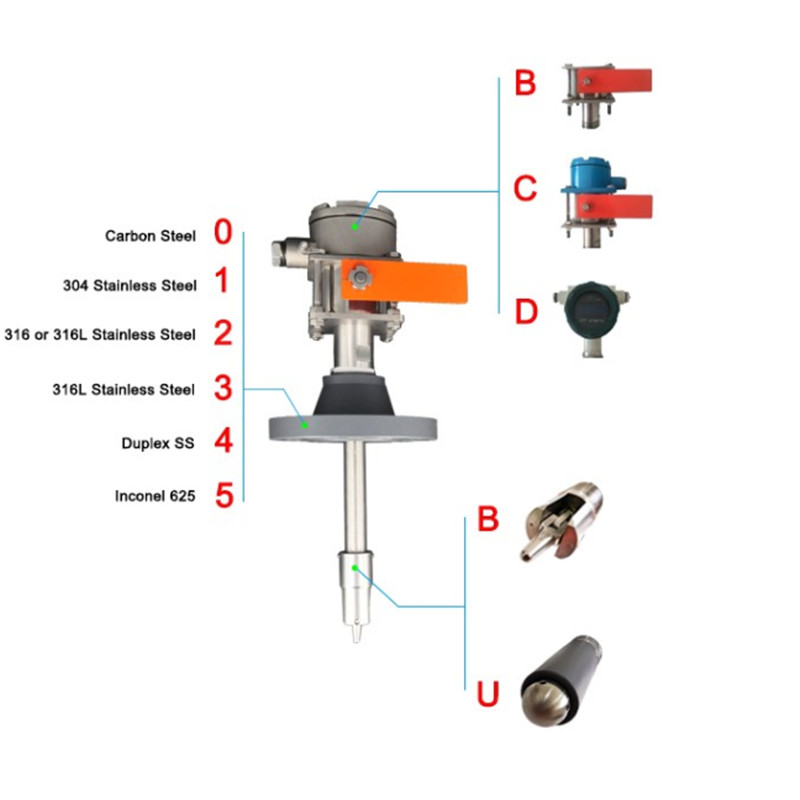

Three trigger type:

1. Bi-directional

2. Bi-directional Feather

3. Uni-directional

Three Pig Indicator types are available:

1. B_Manual reset flag

2. C_Manual reset flag combined with electrical switch output

3. D_Digital display combined with electrical switch output

Three mounting types:

1. 2″flange connection

2. 2″welded nipple

3. 2″welded base- NPT nipple connection

Features of EMT Pig Signaller

It is suitable for pipe sizes starting from 2" and above.

Various design pressure options are available, ranging from ANSI 150# to ANSI 2500# for the 2" flange connection.

The boss connection can handle the highest design pressure of 10,000 Psi (69 MPa).

The working temperature range spans from -20ºC to +120ºC. In case of operating temperatures outside this

range, special seals can be provided.

The trigger mechanism of the signaller is designed without dynamic seals, ensuring both leak prevention and

trigger flexibility (excluding the boss connection with pop-up indicator or digital display). The flag of the signaller

is interactive with the trigger mechanism.

Furthermore, the online checking of the trigger mechanism's flexibility is possible.

It can fulfill the need for adjusting the insert depth as required.

The Pig Signaller is designed for ease of operation, demonstrating proven durability and requiring minimal maintenance.

It is compatible with various types of pipeline pigs, including Foam Pig, Metal Bodied Pigs, Spheres, and Intelligent

Detection Pig, making it suitable for diverse pig applications.

Pig Signaller - flange connection

| |||||

Pig Signaller Basic Feature or Parameter | |||||

Pig Indicator code Item | B | C | D | ||

Type | Intrusive | ||||

Indicator feature | Manual reset flag | Manual reset flag combined with electrical signals | Date and time display combined with electrical signals | ||

Installing type | 2″Flange.As per ASME B16.5 (CLASS150~2500) | ||||

Plug body length | 200mm/Meet the actual needs | ||||

Operating temperature | —20~120℃/Meet customer requirements | ||||

NACE MR – 01- 75 | Yes | ||||

Ingress protection | IP65/IP66 | ||||

Explosion-proof class | ExdⅡ BT4 | ExdⅡ BT4 | |||

Remove under pressure | NO | ||||

Bidirectional Pig Signaller Optional Feature | |||||

√ Standard configuration | X Optional configuration | — None | |||

Trigger type /U-Uni-directional*) | √/X/X | ||||

Trigger mechanism-Flag interaction | —/√ | —/√ | —/— | ||

Internal part material | √/X/X | ||||

Flange/Body material (PTFE Coated A105N/304SS/316LSS/DSS/INCONEL /As per MR) | √/X/X/X/X/X | ||||

The position of Internal liquid surface (High_Need to heating/Low_With no need for heating) | √/X | ||||

Junction box material (Aluminium alloy/316SS) | —/— | √/X | √/— | ||

Switch type (DPDT/SPDT) | —/— | X/√ | X/√ | ||

Switch rating (DC24V 3A/DC24V 5A) | —/— | √/X | √/— | ||

Electrical connection size (M20×1.5(F)/1/2″NPT(F)) | —/— | √/X | √/— | ||

* Standard configuration of Uni-directional trigger is ball shape. | |||||

Corresponding relations between trigger and Insert depth (In pipe) | |||||

Trigger type | Bi-directional | Bi-directional feather | Uni-directional | ||

Insert depth (In pipe) | 21mm | 30mm | 13mm | ||

Why Choose Us