Function and installation of Gauging Disc!

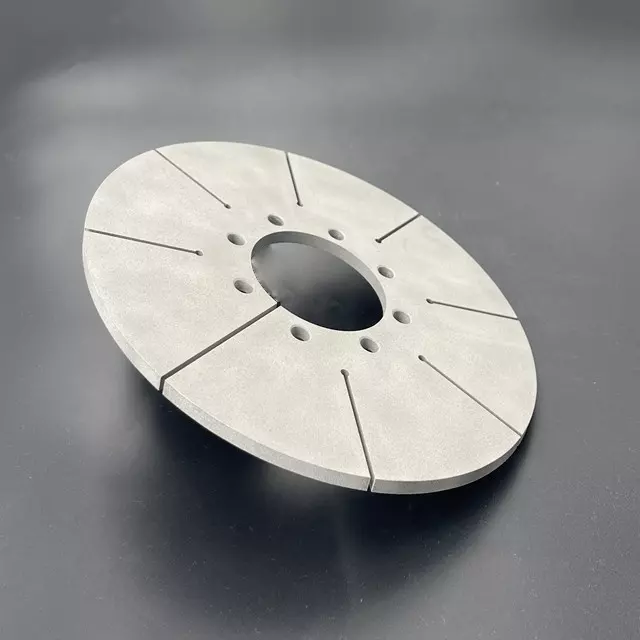

Description

The Gauging Disc is a circular aluminum plate of a certain specification. The outer edge is generally divided into 12 equal parts. It is hung on the pig and runs in the pipeline to measure the factors restricting the passage of the detector. Such as the maximum deformation and the minimum elbow in the pipeline.

Diameter measuring plates of different specifications shall be used for pipe diameters of different specifications. And the proportion varies according to 90%, 85% and 80% of the inner diameter of the pipe. The thickness of this product is also different, including 3mm, 5mm, 6mm, etc.

Installation of Gauging Disc

It is on the common pig, and the Bi-Di disc pig is the best. Because the Bi-Di disc has better support than the cup.

According to PII requirements, the installation position is generally in front of the first sealing disc at the tail end of the Bi-Di disc pig. Between this product and the sealing disc adding a gasket . If necessary to add two washers to increase the bending space of it.

Data Collection after Operation

Operating conditions (gas volume, pressure, speed, receiving and launching time, etc.).

After receiving the ball, check the results of cleaning (dirt type, amount of dirt, etc.)

After taking the pig out of the spherical cylinder, carefully remove this product and clean it. Number its 12 equal parts, and then start (1-7; 2-8, etc.) to measure the diameter change of it.

Place the it horizontally and measure the height from the horizontal plane after each bisection bending.

Precautions for Its Operation

The installation position shall be clear.

Be careful not to damage the it during the process of loading the pig with caliper plate into the launcher and taking out the receiver.

Accurately record various operating parameters.

Complete the its operation report in time.