Shenyang EMT Piping Technology Co., Ltd

Shenyang EMT Piping Technology Co.,Ltd is formerly known as Shenyang Institute Of Sources Technology Development, which was found in 1993, as one of the first companies to develop pigging products in China. As the company gradually expanded, EMT came into being in 2004. EMT mainly produce pipeline pig, pig signaller, corrosion coupon, chemical injector, insulation joint and quick opening closure, who has now become a scientific research enterprise in collection of research, development, sales and service. Daqing Oilfield and Liaohe Oilfield are our long-term domestic partners. You could enjoy no MOQ and prompt delivery from us because of our advanced management concepts and reliable raw material supplier. Considering for customers, let production transparent are EMT's tenets.

-

At EMT, we take pride in delivering precision-engineered corrosion monitoring solutions that meet the highest industry standards. In this recent case, we successfully completed a large-volume order of corrosion probes for a long-term international client in the oil and gas sector. This shipment highlights our attention to detail, modular packaging capabilities, and commitment to quality assurance throughout the production and delivery process.

Details -

As part of our commitment to delivering high-performance pipeline monitoring solutions for the global oil and gas industry, Shenyang Emt Piping Technology Co.,ltd. is proud to announce the successful completion of a new batch of pig signal indicators, precision-engineered for use in critical petroleum and natural gas pipeline systems. These units have successfully passed factory testing and are now awaiting final packaging and international shipment.

Details -

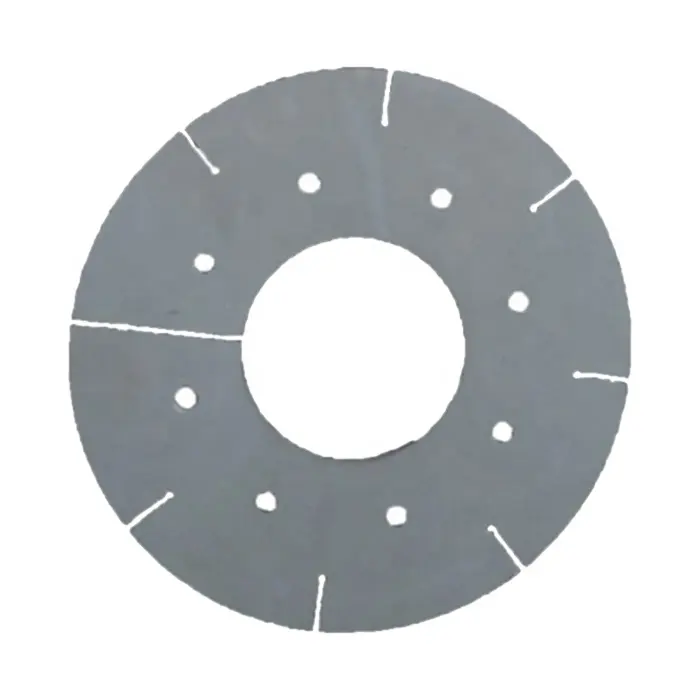

At Shenyang Emt Piping Technology Co.,ltd., we are dedicated to delivering high-quality, precision-engineered solutions for corrosion monitoring systems. In this case, we successfully completed the production and quality inspection of a batch of corrosion coupons and coupon holders, custom-built for an international client in the oil and gas sector.

Details -

Project Overview In December 2025, EMT successfully delivered a batch of portable corrosion monitoring probes to a key customer in the oil & gas industry. These devices are designed for on-site corrosion rate measurement and real-time structural integrity monitoring of pipelines, tanks, and other metallic infrastructure. The corrosion detection systems are housed in rugged protective cases for safe transport and long-term durability in field environments. Each unit integrates a digital handheld display, corrosion sensors, and connection cables, enabling fast deployment and accurate data collection in remote or industrial locations. This project highlights EMT’s expertise in customized field inspection tools, non-destructive testing (NDT), and OEM corrosion monitoring solutions.

Details

-

As part of our ongoing commitment to building strong, lasting relationships with global partners, two of our dedicated team members from EMT recently traveled to Shanghai to meet with a valued international client. This visit marked a meaningful step in strengthening our cooperation and exploring future opportunities in the industrial pipeline equipment sector.

19-01-2026 -

We take pride in not only designing and manufacturing high-performance corrosion monitoring equipment, but also offering on-site installation and technical support to ensure optimal performance of every system we deliver.

05-01-2026 -

We were delighted to host a delegation of international clients at our manufacturing facility this week, marking another significant step forward in our global business partnerships. The visit showcased our advanced production capabilities, high-quality standards, and commitment to transparency and collaboration.

31-10-2025

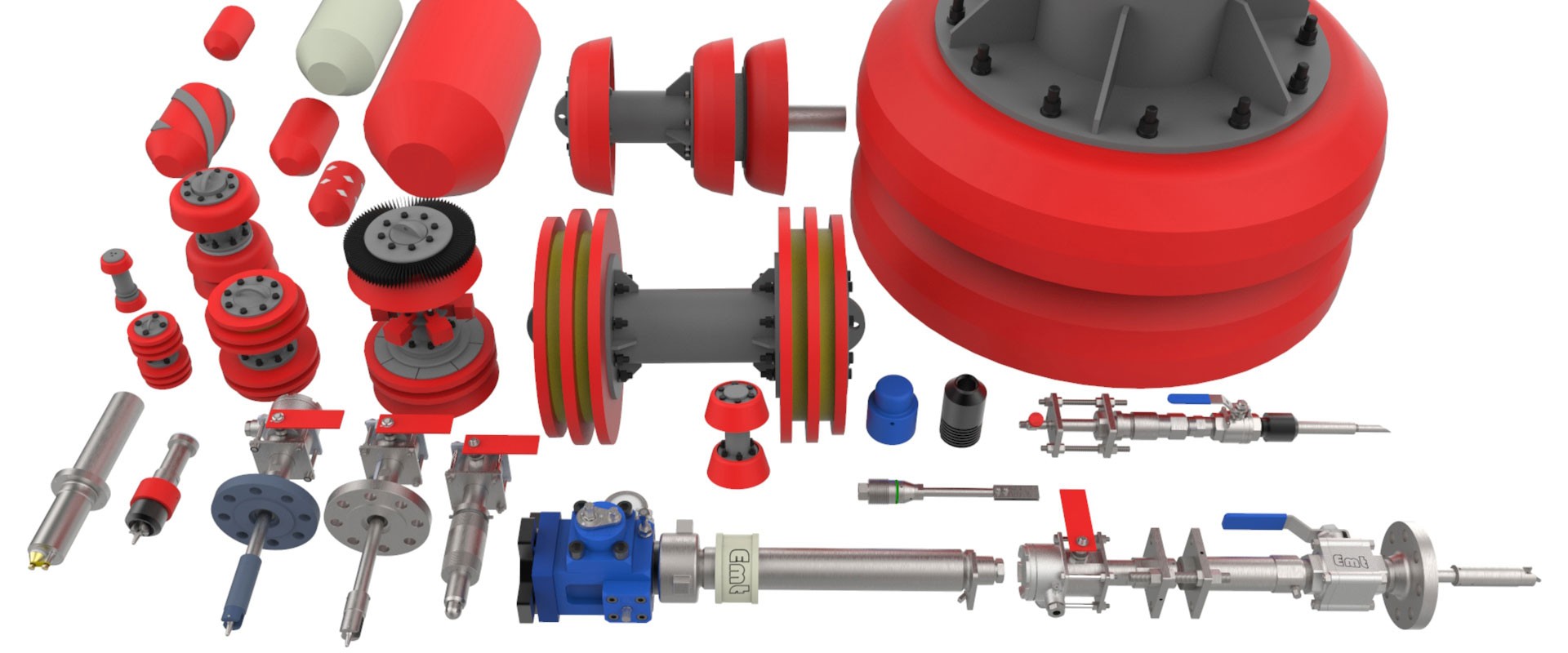

With Pressure Removal Tool

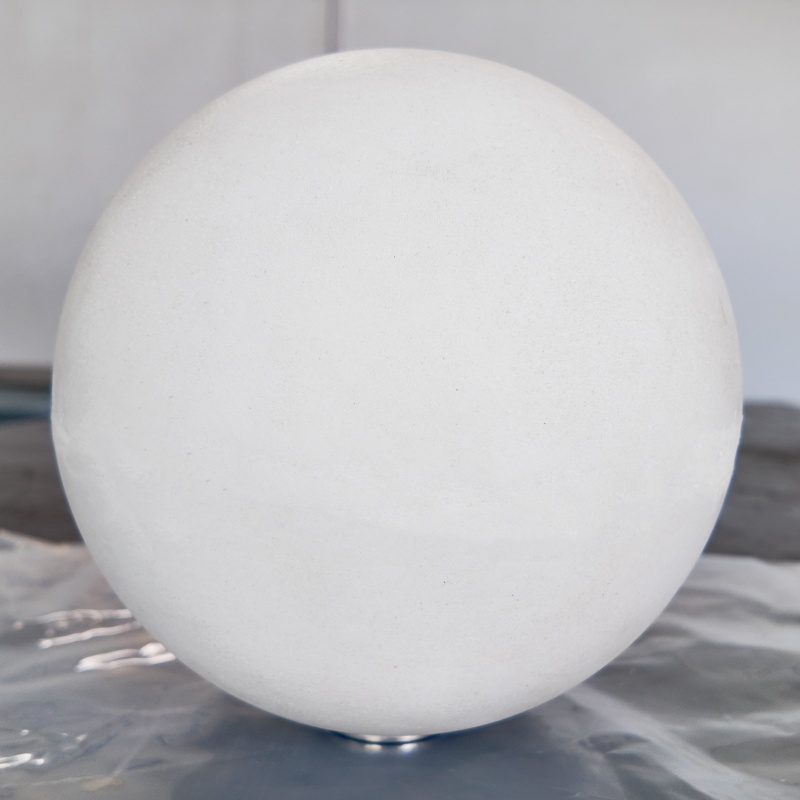

Brush Foam Pig

Carbon Steel Pig

Jet Pipeline Pig

Cup Pipeline Pig

Chemical Injector Quill

Welded Removable Pig Signaller

Corrosion Probe

Bi-di Disc Pig

Criss Cross Foam Pig

Removable Pig Signaller

Flange Pig Signaler

Corrosion Coupon

Quick Opening Closure Vertical

Solid Cast Pig

Solid Cast Cleaning Pig

Cup Pig

Cups Pipeline Pig

Pipeline Pig

Retrieval Tool