-

Corrosion Probes Shipment with Modular Packaging for International Client!

At EMT, we take pride in delivering precision-engineered corrosion monitoring solutions that meet the highest industry standards. In this recent case, we successfully completed a large-volume order of corrosion probes for a long-term international client in the oil and gas sector. This shipment highlights our attention to detail, modular packaging capabilities, and commitment to quality assurance throughout the production and delivery process.

Details -

Precision Pig Signal Indicators Ready for Global Shipment in Oil & Gas Pipeline Applications!

As part of our commitment to delivering high-performance pipeline monitoring solutions for the global oil and gas industry, Shenyang Emt Piping Technology Co.,ltd. is proud to announce the successful completion of a new batch of pig signal indicators, precision-engineered for use in critical petroleum and natural gas pipeline systems. These units have successfully passed factory testing and are now awaiting final packaging and international shipment.

Details -

Custom-Manufactured Corrosion Coupons and Holders for Industrial Corrosion Monitoring!

At Shenyang Emt Piping Technology Co.,ltd., we are dedicated to delivering high-quality, precision-engineered solutions for corrosion monitoring systems. In this case, we successfully completed the production and quality inspection of a batch of corrosion coupons and coupon holders, custom-built for an international client in the oil and gas sector.

Details -

Delivery of Portable Corrosion Probes for Field Corrosion Monitoring!

Project Overview In December 2025, EMT successfully delivered a batch of portable corrosion monitoring probes to a key customer in the oil & gas industry. These devices are designed for on-site corrosion rate measurement and real-time structural integrity monitoring of pipelines, tanks, and other metallic infrastructure. The corrosion detection systems are housed in rugged protective cases for safe transport and long-term durability in field environments. Each unit integrates a digital handheld display, corrosion sensors, and connection cables, enabling fast deployment and accurate data collection in remote or industrial locations. This project highlights EMT’s expertise in customized field inspection tools, non-destructive testing (NDT), and OEM corrosion monitoring solutions.

Details -

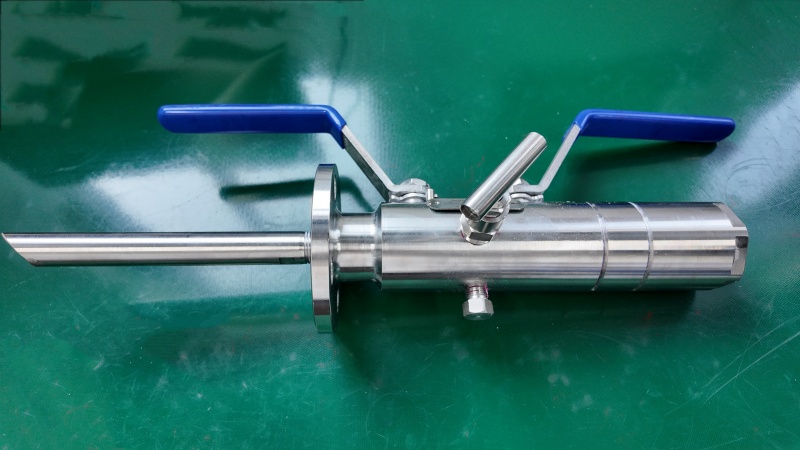

High-Performance Hydraulic Corrosion Coupons and Chemical Injection Quills for Oil & Gas Pipelines

In the oil and gas industry, ensuring pipeline integrity and process safety is non-negotiable. One of our recent projects involved the custom manufacturing and delivery of hydraulic corrosion monitoring coupons and chemical injection quills, designed to be installed in high-pressure oil and gas pipeline systems. This case study showcases how our engineering team developed a complete corrosion monitoring and chemical dosing solution to help our client in the petroleum sector maintain operational efficiency and extend pipeline lifespan.

Details -

Precision Chemical Injection Quill Solution for Pipeline Corrosion Control

At Shenyang Emt Piping Technology Co.,ltd., we specialize in delivering high-performance flow control solutions for industrial applications. One of our latest success stories involves the custom design and supply of chemical injection quills for a large-scale pipeline system in the petrochemical sector. This case study demonstrates how our injection quill solution helped our client achieve accurate dosing, corrosion control, and operational efficiency.

Details