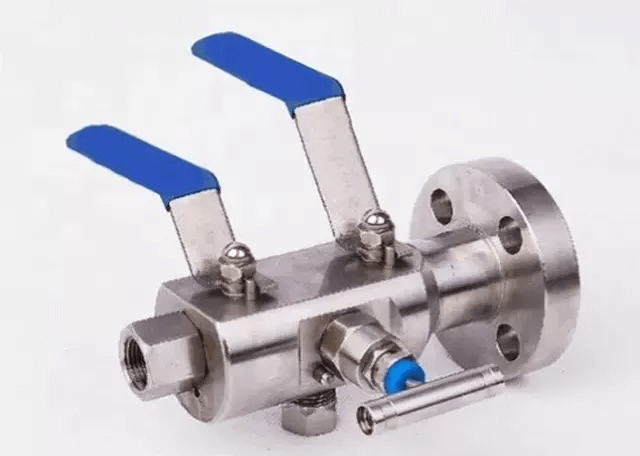

Application of DBB Ball Valve!

DBB is used in applications that require critical isolation. This ensures that no leakage occurs. What type of choice depends on the type of application and service. For example, in liquid services near waterways or municipalities, double expansion gate valves with DBB capability are preferably used for critical isolation. Because they provide tight mechanical seals upstream and downstream at the same time, they are usually not affected by pressure changes or vibration.

Another application using DBB and DIB valves is instrument calibration. Each shut-off valve in the instrument system must be tightly sealed. Even small leakage will lead to instrument calibration errors, and incorrect instrument factors will continue until the next calibration operation. So this may cause huge money to end users. Selecting the right API-validated DBB Ball Valve or DIB valve can help ensure that the correct calibration is performed almost every time.

The mechanical wedge action of the double check valve compresses the upstream and downstream seals against the valve body. This means that no help from line pressure is required to affect the positive seal. When determining whether to use DBB Ball Valve or DIB valves and which definition (API or OSHA) to follow. So it is important to clearly understand similarities and differences. It is also important to consider the specific application of the valve and ensure that the characteristics required for isolation are fully tested during the factory acceptance test of the valve.