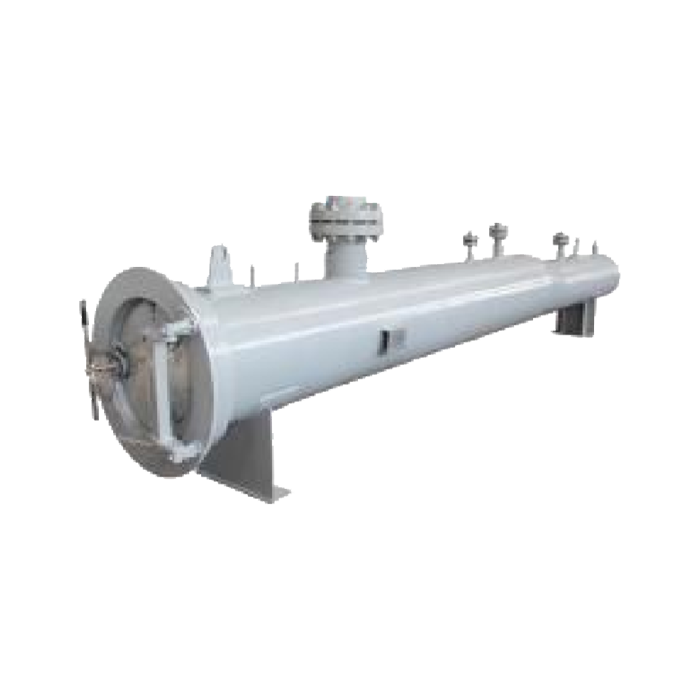

EMT Customized Pig Launcher and Receiver

- EMT

- Shenyang

Pig lanucher and receiver are the sections of the pipeline which allow the pig to enter and exit the pipeline. Pig lanucher and receiver are generally funnel, Y-shaped sections of the pipe which can be pressurized or depressurized and then safely opened to insert or remove PIGs.

Pig lanucher and receiver could be horizontal or vertical as your request.

Pig Launcher And Pig Receiver Description

Benefits of the Pipeline Pig Launcher:

Reasonable Design:

The Pipeline Pig Launcher is designed with careful consideration of functionality and efficiency.

The design ensures smooth and effective reception of wax removal balls.

Safety and Reliability:

The launcher is built with safety features to prevent accidents and ensure reliable operation.

It undergoes rigorous testing and meets industry standards to ensure safe and efficient pigging operations.

Compact and Convenient Installation:

The launcher's compact design allows for easy installation in various locations.

Its convenient installation process saves time and effort, reducing downtime during setup.

Unattended, Regular, Automatic, and Continuous Pig Collection:

The Pipeline Pig Launcher operates automatically, eliminating the need for constant manual monitoring.

It can be programmed to collect pigs at regular intervals, ensuring continuous operation without interruptions.

Labor Intensity Reduction:

By automating the pigging process, the Pipeline Pig Launcher reduces the need for manual labor.

Employees are relieved from the physically demanding task of pig collection, improving their working conditions.

Cost Savings:

The application of the Pipeline Pig Launcher reduces the operational costs associated with pigging operations.

It eliminates the need for dedicated personnel to manually collect pigs, resulting in reduced labor expenses.

Improved Economic Benefits:

The Pipeline Pig Launcher enhances the economic benefits of oil fields by optimizing pigging operations.

Cost savings and increased operational efficiency contribute to improved profitability for the oil field.

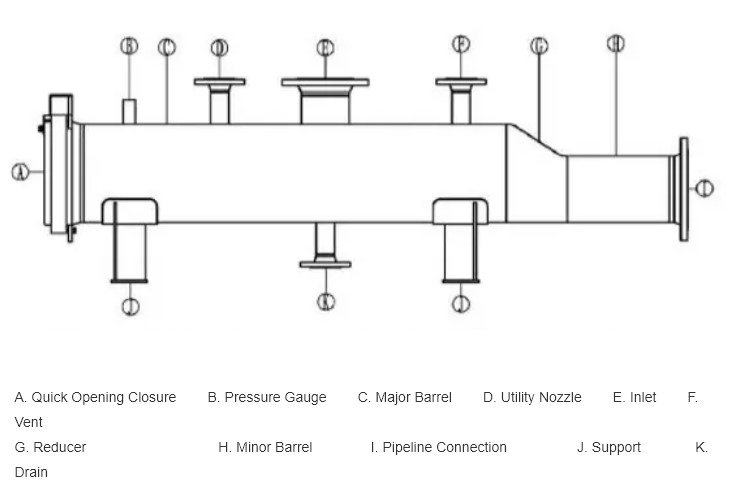

Pig Launcher Structure Drawing (Model NO.PL-BLT)

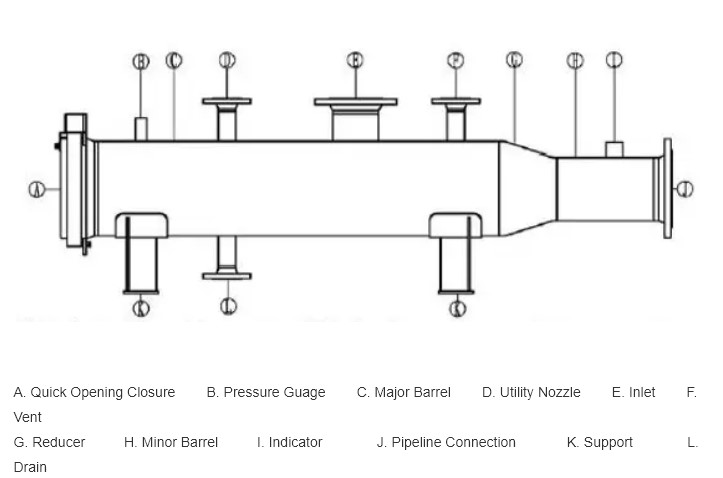

Pig Receiver Structure Drawing (Model NO.PR-BLT)

| Design Conditions | ||

| 1. | Pipeline Size | From 6" up to 56" |

| 2. | Design Code | ASME VIII Div 1; ASME B31.3; ASME B31.4; ASME B31.8, etc. |

| 3. | Design Factor | 0.5, 0.6, 0.7, etc. |

| 4. | Corrosion Allowance | 0-5mm or more |

| 5. | Design Pressure | CL150, CL300, CL600, CL900, CL1500, CL2500, or as required. |

| 6. | Design Temperature (Min/Max) | -50℃ / 200℃ |

| 7. | Closure Type | Band Lock and Clamps Type Quick Opening Closure |

| 8. | Installation Orientation | Horizontal, Vertical, Inclined |

| 9. | Applicable Medium | Gas, Oil, Petroleum, Chemical Materials, Water, etc. |

| Structure and Main Materials | ||

| 1. | Major Barrel/Min Barrel | ASTM A106, ASTM A516 Gr.70, APIX42 X52 X60 X65, or as required. |

| 2. | Quick Opening Closure (with interlock system) | ASTM A515 Gr.70, ASTM A516 Gr.70, ASTM A105, ASTM A350 LF2 Class1, ASTM A694 F42 F46 F48 F50 F52 F56 F60 F65 F70, or as required. |

| 3. | Sealing Ring for the Closure | Viton, Nitrile |

| 4. | Saddle Support | Q235, or as required. |

| 5. | Flange | ASTM A105, ASTM A694 F70, or as required. |

| 6. | Lifting Lug/Eyes | Q235, or as required. |

| 7. | Grounding | Yes |

| 8. | Name Plate | Stainless Steel, or as required. |

| Certificates | ||

| 1. | ASME U Stamp Certificate | Applicable |

| 2. | Third Party Inspection | BV, SGS, ABS, DNV, or as required. |