PU Coating Foam Pig

- EMT

- Shenyang, China

- 15 days

- 200 sets/month

PU Coating Foam Pig is a foam pig. Its inner core is polyurethane foam. And PU Coating Foam Pig surface is covered with polyurethane. This structure makes it not only portable as a foam pig but likewise has certain corrosion resistance. Therefore, this smooth foam ball can be made use of for pipe cleaning as well as inner evaluation at the preliminary phase of pipeline building and construction. And since PU Coating Foam Pig has specific sealing residential, Foam Pig can additionally be made use of to obstruct the fluid.

Polly Pig Description

1. Name: PU Coating Foam Pig

These foam pig is used for liquid removal, drying, sweeping and general cleaning. Foam pig is our most popular style of cleaning pig due to they are very cost effective and versatile.

2. Polly Pig Performance

The interior is foamed from a polyurethane material and the surface is coated with a polyurethane elastomer coating;

Good flexibility and certain wear resistance;

The deformation amount can reach 50%, which is a kind of foam pig with a wide application;

Used for scrubbing, descaling and fluid isolation of pipes.

3.Polly Pig Technical Parameters:

Starting pressure: 0.02-0.1Mpa Withstand voltage: 7Mpa

Common density: 100-120kg/m3 Tensile rate: 320%

Compression ratio: 50% wear resistance: 4mm/100KM

One working distance: 0KM-150KM

Working temperature: -30 ° C -100 ° C

4. Polly Pig Material: EMT manufactures foam pigs for all pipe sizes.

These molded polyurethane foam pig is available in three densities:

Light density – 0.02-0.03g/cm3

Medium density –0.08-0.12g / cm3

Heavy density – 0.13-0.16g/ cm3

5. Pipeline Pig Feature: high wear resistance, Good cleaning performance and low-cost.

6. Pipeline Pig Advantage:

(1) They are light weight and flexible.

(2) nice cleaning efficiency,

(3) accurate location tracking.

7. Pipeline Pig Drying remark: Light density foam pig’s water absorbing capacity is better than high density foam pig.

8. Pipeline Pig Specification

Name | PU Coating Foam Pig |

Material | Polyurethane Light density – 0.02-0.03g/cm3 Medium density –0.08-0.12g / cm3 Heavy density – 0.13-0.16g/ cm3 |

Feature | 2. Good cleaning performance 3. low-cost |

Packing way | packed with inner plastic film and outer plywood wooden case. |

Payment | TT/LC |

Advantage | 1. They are light weight and flexible. 2. nice cleaning efficiency 3. Accurate location tracking. 4. The precision can reach to plus or minus 5cm |

9. Pipeline Pig Usage

Foam pig is a versatile type of pipeline cleaning device. Foam pig is used for drying, cleaning and product removal operations. A few of the industries utilizing foam pig is the oil and gas, food and beverage, mining, chemical and petrochemical, cosmetic, and pharmaceutical industries. Because they are lightweight and flexible, foam pig is able to negotiate uncommon piping, fittings, and valves.

Minimum Order Quantity(MOQ):1 Piece.

Payment term:T/T at sight or L/C.

Packaging & Shipping

Packaging will choose the adaptation methods according to the requirements, size, weight, transportation distance, and etc. Package purpose prevents deformation, pollution, and damage in the process of transportation, loading, and unloading.

If you have a special demand for the package, please just tell us before ordering . we can produce as your request.

Our Services

1. Many kinds of pipe cleaning pig with a different type to meet different requirements.

2. Samples will be offered to attest to the quality and our services.

3. The fastest feedback!

4. The fastest delivery time.

5. 24 hours, 7 days online.

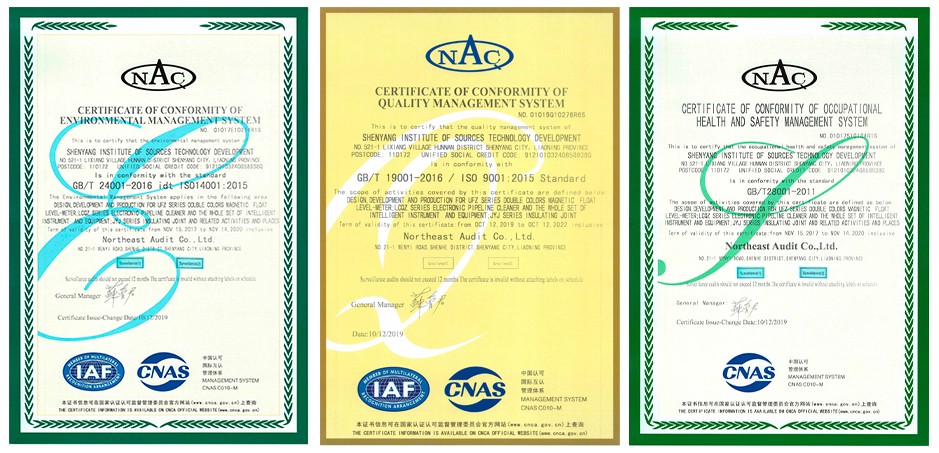

Company Information

We Shenyang EMT Pigging Technology Co., Ltd. was founded in 2004 has developed to a science and technology development enterprise that combines science development, product development, production, sales, and service as a whole. The meters, instruments, and equipment developed have been widely used in petroleum, power, chemical, liquor-making, metallurgy, mechanical industries. Our institute has professional R&D, sales, site and after service staff with strong strength of R&D, development, production, and installation.