Welded Removable Pig Signaller With Ball Valve

- EMT

- Shenyang, China

- 15 days

- 200 sets/month

EMT Welded Removable Pig Signaller With Ball Valve is used to provide confirmation of the movement of pipeline pigs through a pipeline. Welded Removable Pig Signaller With Ball Valve is normally positioned at both the pig launching and pig receiving stations and at key points along a pipeline.

Welded Removable Pig Signaller With Ball Valve

EMT Pig Signaller(Pig Passage Indicator)

The EMT Welded Removable Pig Signaller With Ball Valve is a valuable tool designed for confirming and monitoring the movement

of pigs within pipelines. It serves the crucial purpose of ensuring accurate tracking and progress of pigs during pipeline operations.

This specialized equipment combines a welded removable pig signaller with a ball valve, offering enhanced functionality and convenience.

The integration of a ball valve allows for controlled flow and isolation during pigging operations, providing flexibility and control.

The removable design of the signaller facilitates easier maintenance and inspection, improving accessibility and reducing downtime.

By strategically positioning the signaller at pig launching, pig receiving stations, and key points along the pipeline, operators gain

visibility and control over pig movement, enhancing overall pipeline operations and maintenance. The EMT Welded Removable Pig

Signaller With Ball Valve is a reliable solution that optimizes pig tracking, improves operational efficiency, and ensures the integrity

of pipeline systems.

Benefits of EMT Pig Signaller

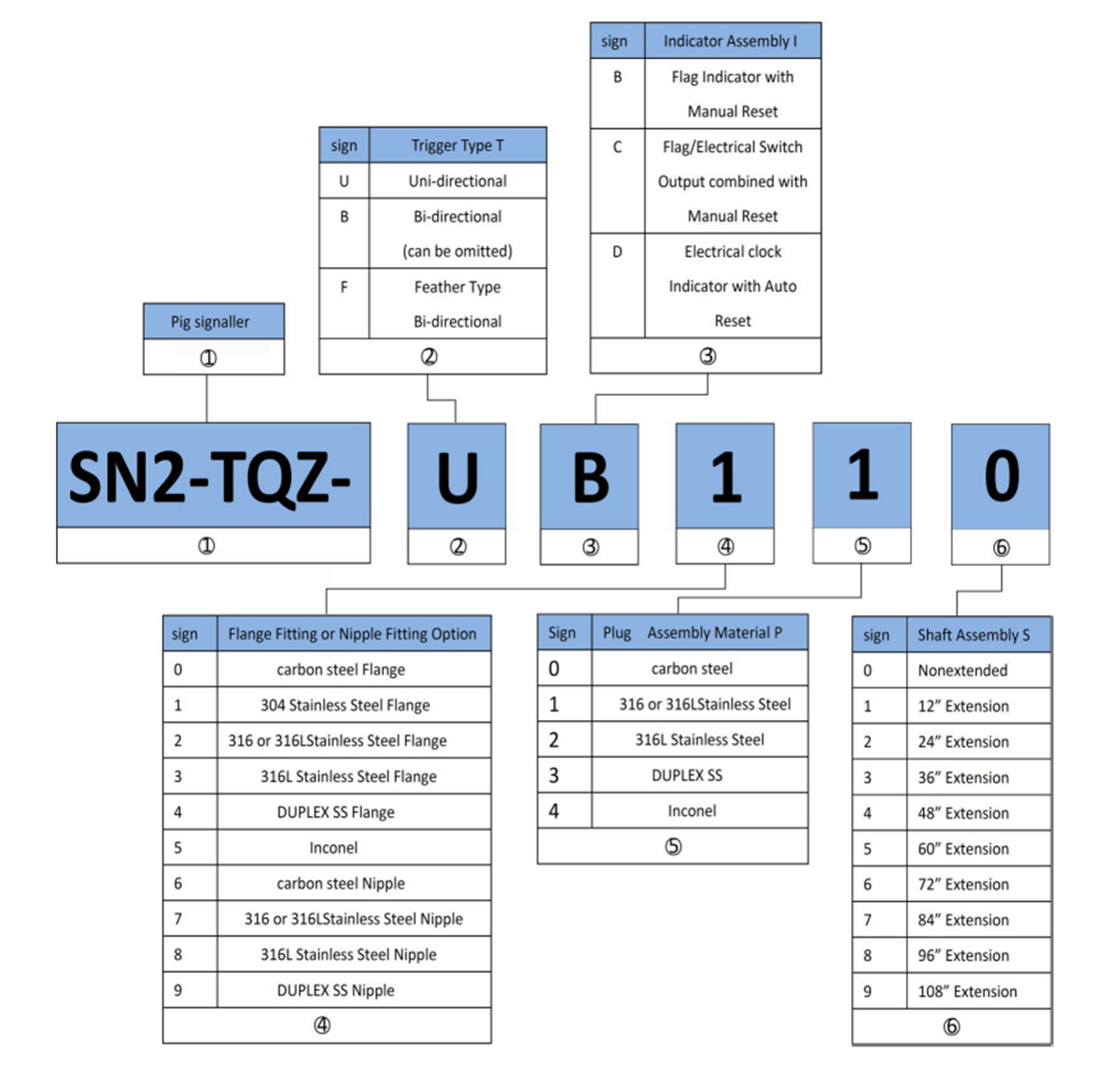

Three trigger type:

1. Bi-directional

2. Bi-directional Feather

3. Uni-directional

Three indicator types are available:

1. B_Manual reset flag

2. C_Manual reset flag combined with electrical switch output

3. D_Digital display combined with electrical switch output

Three mounting types:

1. 2″flange connection

2. 2″welded nipple

3. 2″welded base- NPT nipple connection

Features of EMT Pig Signallers

l Suitable for pipe sizes from 2” upwards

l A range of design pressure from ANSI 150 # to ANSI 2500 # are available for 2 "flange connection,

The highest design pressure is 10000Psi(69MPa) for boss connection.

l The working temperature range is -20ºC to +120ºC. Special seals can be provided for operating temperatures outside this range

l Trigger mechanism does not use dynamic seals therefore both prevent leakage and ensure trigger flexibility(The boss connection, with pop-up indicator or the digital display is excluded). The flag is interactivity with the trigger mechanism, therefore, the flexibility of trigger mechanism can be checked online.

l The requirement about adjusting Insert depth can also be met.

l Easy to operate, Proven durability, minimal maintenance required.

Suitable for all types of pipeline pigs such as Foam Pig, metal Bodied Pigs, Spheres, Intelligent Detection Pig

The EMT Welded Removable Pig Signaller With Ball Valve is a valuable tool designed for confirming and monitoring the movement of pigs within pipelines. It serves the crucial purpose of ensuring accurate tracking and progress of pigs during pipeline operations. This specialized equipment combines a welded removable pig signaller with a ball valve, offering enhanced functionality and convenience. The integration of a ball valve allows for controlled flow and isolation during pigging operations, providing flexibility and control. The removable design of the signaller facilitates easier maintenance and inspection, improving accessibility and reducing downtime. By strategically positioning the signaller at pig launching, pig receiving stations, and key points along the pipeline, operators gain visibility and control over pig movement, enhancing overall pipeline operations and maintenance. The EMT Welded Removable Pig Signaller With Ball Valve is a reliable solution that optimizes pig tracking, improves operational efficiency, and ensures the integrity of pipeline systems. | |||||||

Basic Feature or Parameter | |||||||

Indicator code Item | B | C | D | ||||

Type | Intrusive | ||||||

Indicator feature | Manual reset flag | Manual reset flag combined with electrical signals | Date and time display combined with electrical signals | ||||

Installing type | 2″Nipple welded. Design pressure up to 10000Psi | ||||||

Plug body length | Meet the actual needs | ||||||

Operating temperature | —20~120℃/Meet customer requirements | ||||||

NACE MR – 01- 75 | Yes | ||||||

Ingress protection | IP65/IP66 | ||||||

Explosion-proof class | ExdⅡ BT4 | ExdⅡ BT4 | |||||

Include isolation valve | Yes | ||||||

With bypass valve | Yes | ||||||

With bleed valve | Yes | ||||||

Remove under pressure | Yes(The whole machine comes with a simple retriever_ two whole threaded studs) | ||||||

Pig Signaller Optional Feature | |||||||

√ Standard configuration | X Optional configuration | — None | |||||

Trigger type | X/X/√ | ||||||

Trigger mechanism-Flag interaction | —/√ | —/√ | —/— | ||||

Internal part material | √/X/X | ||||||

Flange/Body material (PTFE Coated A105N/304SS/316LSS/DSS/INCONEL /As per MR) | √/X/X/X/X/X | ||||||

The position of Internal liquid surface (High_Need to heating/Low_With no need for heating) | —/√ | ||||||

Junction box material (Aluminium alloy/316SS) | —/— | √/X | √/— | ||||

Switch type(DPDT/SPDT) | —/— | X/√ | X/√ | ||||

Switch rating (DC24V 3A/DC24V 5A) | —/— | √/X | √/— | ||||

Electrical connection size (M20×1.5(F)/1/2″NPT(F)) | —/— | √/X | √/— | ||||

Retriever (Two full thread stud/ special tool) | √/X | ||||||

Insert depth adjustment range (±10mm) | √ | ||||||

* Standard configuration of Uni-directional trigger is ball shape. | |||||||

Corresponding relations between trigger and Insert depth (In pipe) | |||||||

Trigger type | Bi-directional | Bi-directional feather | Uni-directional | ||||

Insert depth (In pipe) | 21mm | 30mm | 13mm | ||||