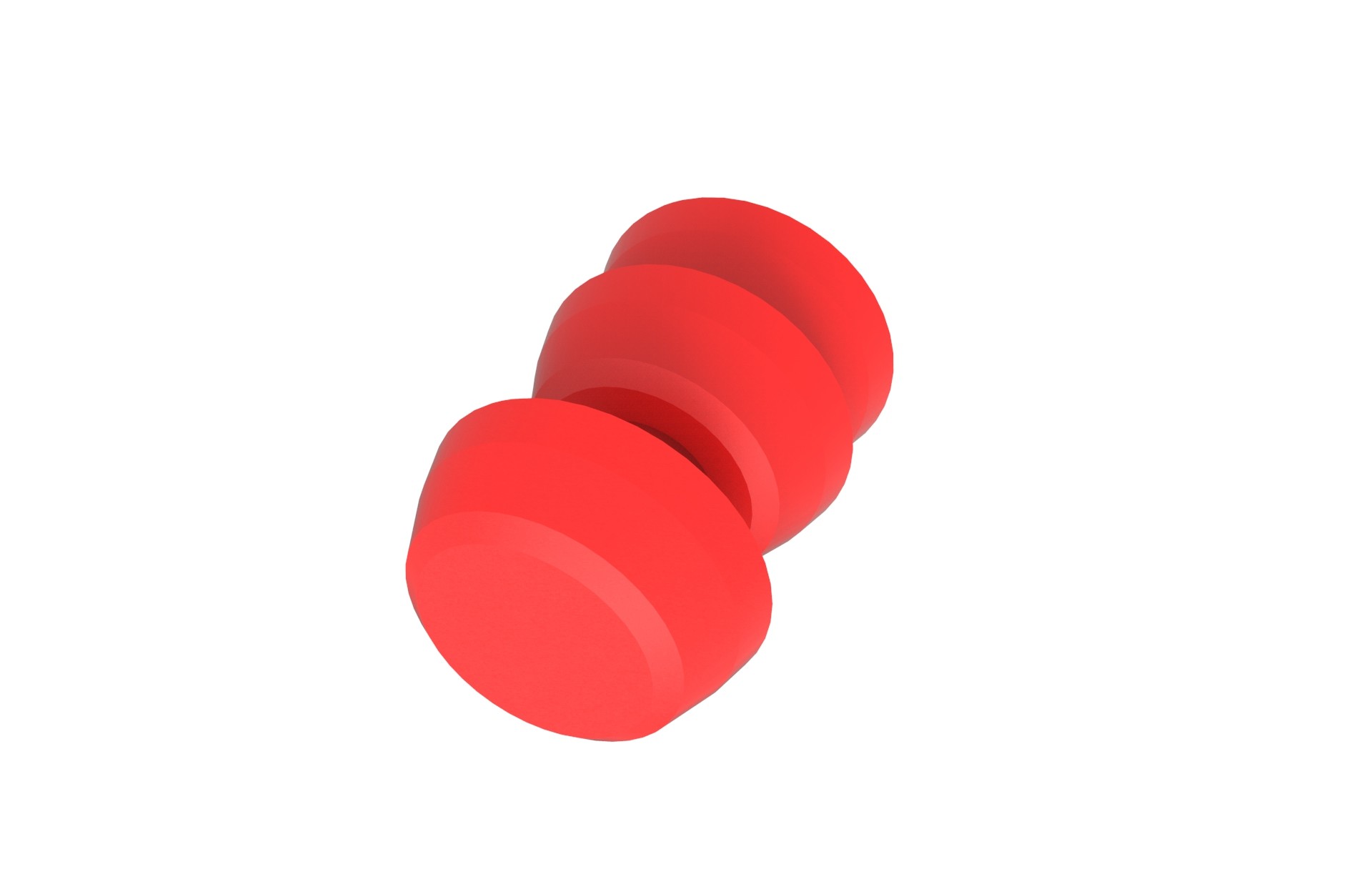

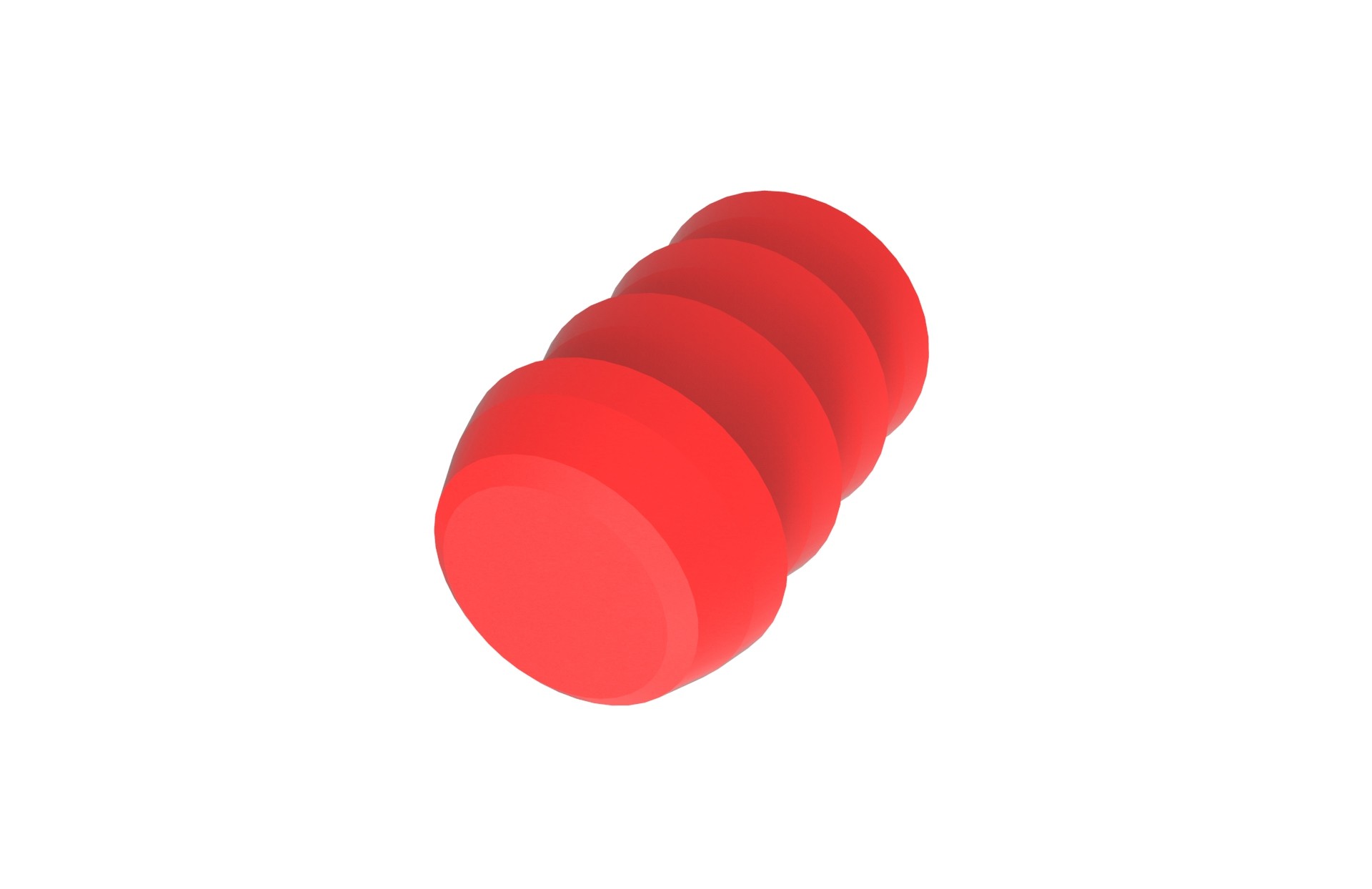

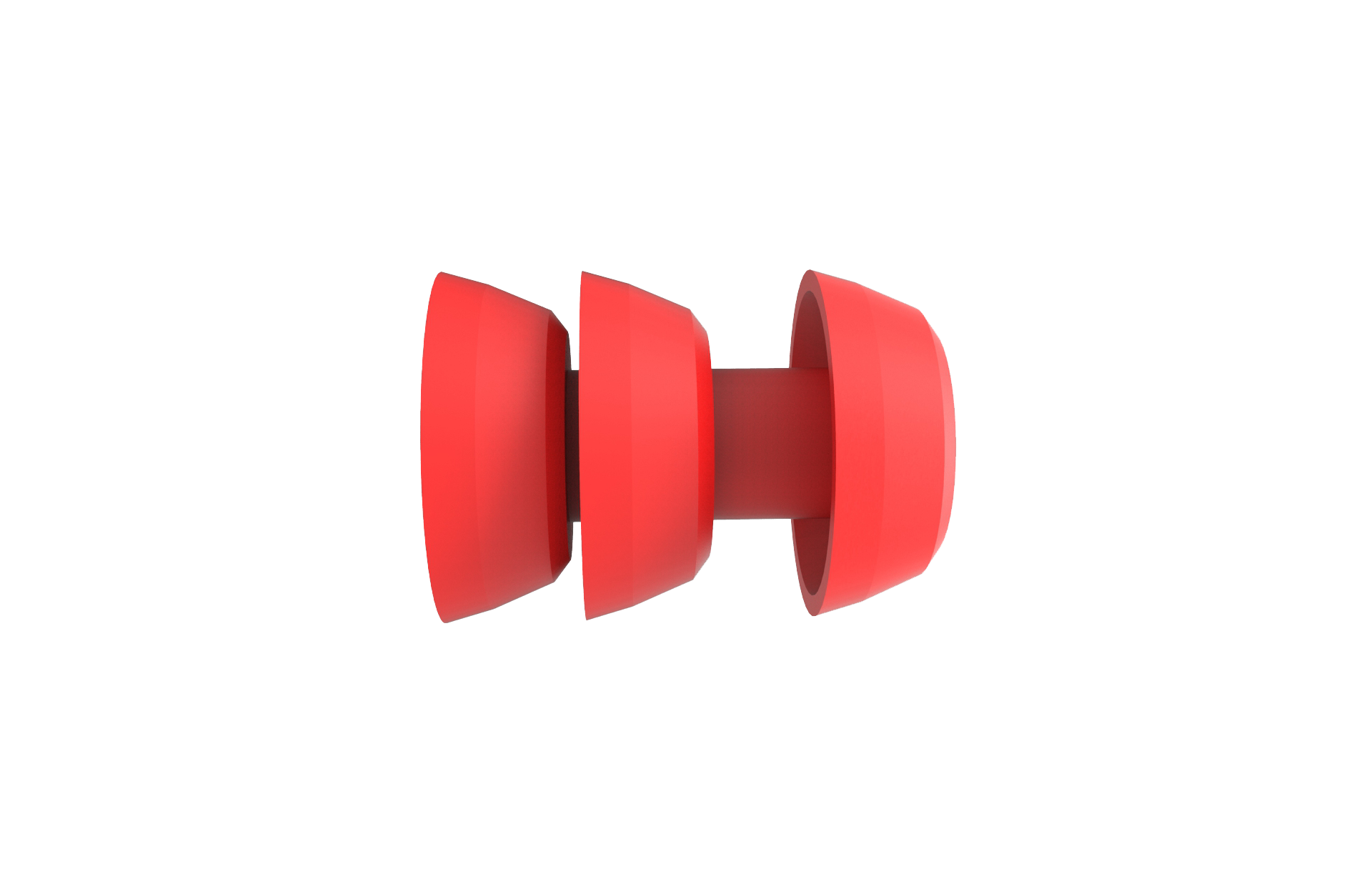

Polyurethane Cup Pig

- EMT

- Shenyang, China

- 15 days

- 200 sets/month

Polyurethane Cup Pig, integrally formed, usually made of polyurethane.

Polyurethane Cup Pig cleaning process

First, the Polyurethane Cup Pig is put into the oil and gas pipeline, injected into the pipeline medium (oil or liquid natural gas), the valve is opened to enter the pipeline to start the cleaning work, the Polyurethane pig is cleaned in the pipeline, and the cleaning is completed into the last section of the pipeline. Close the valve, pull out the last pipe of liquid, open the end pipe valve, and the pipeline pig exits.

Polyurethane Pig Description

1.Introducing the Polyurethane Cup Pig, a highly efficient pipeline cleaning tool designed to deliver

exceptional performance. The main body of this pig is composed of durable polyurethane material

and is equipped with 2-4 sealed cups or discs.

With a proven track record of long-term usage in the Daqing oil field and the Liaohe oil field, our

pipeline pigs have gained recognition for their stability, reliability, and consistent high quality. Positive

feedback from satisfied customers further reinforces their reputation as a trusted solution in the

industry.

The Polyurethane Cup Pig is specifically designed for pre-operation pipeline preparation. It effectively

removes debris and contaminants, ensuring a clean and optimal pipeline before it is put into use.

This versatile pig can be employed in various types of pipelines, catering to different operational

requirements.

Features of Polyurethane Pig:

Polyurethane pigs are renowned for their exceptional characteristics, including excellent wearing

resistance, strong passing ability, effective cleaning performance, accurate location and tracking,

and a low rate of false positives, among others.

Advantages of Polyurethane Pig:

The advantages of utilizing polyurethane pigs are manifold:

Superior Sealing Performance: Polyurethane pigs exhibit remarkable sealing capabilities, ensuring efficient

containment of fluids and preventing leakage or product loss during pipeline operations.

High Wear Resistance: These pigs are highly resistant to wear and abrasion, enabling them to withstand the

demanding conditions encountered in pipelines over extended periods. This durability contributes to their

longevity and reliability.

Report No.TD-20I90117-045N-2 CX99JL03

SUMMARY OF TEST RESULTS | ||||

NO. | TEST PROJECT | UNITS | TEST RESULT | TEST METHOD |

1 | Shore hardness | Shore A | 83 | GB/T531.1-2008 |

2 | DIN abrasion | mm3 | 21 | GB/T53516-1987 |

3 | Akron abrasion | crn3 | 0.0518 | GB/T1689-1998 |

4 | 100%stress at definite elongation | MPa | 3.41 | GB/T528-2009 |

5 | 300%stress at definite elongation | MPa | 5.74 | GB/T528-2009 |

6 | Tensile strength | MPa | 51.2 | GB/T528-2009 |

7 | Elongation at break | % | 1263 | GB/T528-2009 |

8 | Tear strength (right Angle) | kN/m | 77 | GB/T529-2008 |

9 | Resilience rate | % | 34 | GB/T168-2009 |

Company Information