cleaning pig

-

Cleaning Bi-Di Disc Pig

The Cleaning Bi-Di Disc Pig is made of excellent polyurethane raw materials, with high wear resistance, high tear strength, surface opening, double effect of water absorption and cleaning. Cleaning Bi-Di Disc Pigcan solve the task of water absorption and cleaning at the same time. Cleaning Bi-Di Disc Pig has low engineering cost and good cleaning effectadvantage.

Email Details -

Hot

Magnetic Brush Bi-Di Disc Sealing Pig

Rubber material: good sealing performance, maximum 90 degree bending, Suitable for pipeline cleaning in the food hygiene petroleum industry. Magnetic Brush Bi-Di Disc Sealing Pig is equipped with the position and control of the magnets and can be cleaned and tracked in a closed system. Magnetic Brush Bi-Di Disc Sealing Pig Modular design Due to the unified modular system, all components require very few different spare parts, reducing product losses. Suitable for bending radius 3.0 xD.

Email Details -

Hot

Polyurethane Cup Pig

Polyurethane Cup Pig, integrally formed, usually made of polyurethane. Polyurethane Cup Pig cleaning process First, the Polyurethane Cup Pig is put into the oil and gas pipeline, injected into the pipeline medium (oil or liquid natural gas), the valve is opened to enter the pipeline to start the cleaning work, the Polyurethane pig is cleaned in the pipeline, and the cleaning is completed into the last section of the pipeline. Close the valve, pull out the last pipe of liquid, open the end pipe valve, and the pipeline pig exits.

Email Details -

Hot

EMT Customized Pipeline Cleaning Solid Cast Pig

EMT customized pipeline cleaning solid cast pig, integrally formed, made of polyurethane. The solid cast pig is uaually applied to the pipelines containing the medium of water, gas or oil. The pressure difference between the front and the back of the pig pushes the cup pig forward so that the pipeline is cleaned by the cup pig. Solid cast pig has the features of good looking appearance, strong wear resistance performance, etc.

Email Details -

Hot

Pipeline Cleaning Polyurethane Solid Cast Pig

EMT Polyurethane Solid Cast Pig, integrally formed, made of polyurethane. EMT Polyurethane Solid Cast Pig cleaning process First, the solid cast cleaning pig is put into the oil and gas pipeline, injecting into the pipeline the medium (oil or liquid or natural gas), the valve is opened to let the solid cast enter the pipeline to start the cleaning work.

Email Details -

Pipeline Pig Manufacturer Magnetic Pig with Brush

The structure of the Magnetic Pig with Brush is a variety of structures, which can meet various functions such as pigging, rust removal, diameter measurement, replacement, and production isolation. The Magnetic Pig with Brush through a pipe elbow with a minimum radius of curvature of 1.5 times the pipe diameter. The Magnetic Pig with Brush has a running distance of 200 kilometers or more. The appearance quality of the Magnetic Pig with Brush is sprayed and plated to prevent corrosion.

Email Details -

Polyurethane Guide Disc

Polyurethane Guide Disc is the main component of pigs. Based on years of experience in production and on-site actual pigging operations. So we draw on the advanced technology of foreign pipeline companies to continuously improve the outer dimensions and materials of Polyurethane Guide Disc to achieve optimal cleaning. If you want to know more about it please contact us.

Email Details -

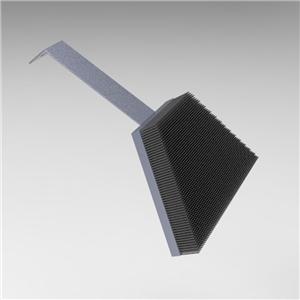

Spring Steel Brush

Oil Gas Pipeline Cleaning Pig Accessory Magnetic Steel Spring Brush Spring Brush is used for cleaning the interior of pipeline where wax, asphaltenes, scale, salt, sand or debris are present.

Email Details -

Steel Brush

Rust removal partner: 360° to steel brush the inner pipeline wall. Steel brush !

Email Details