-

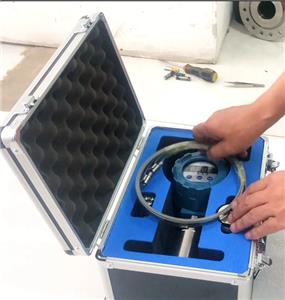

Non-Intrusive Pig Detector For Oil And Gas Pipelines!

Overview Pig Passage Indicator is a mechanically triggered explosion-proof digital display ball indicator. It is usually installed on the ball pipe. And it can detect whether the pig passes. The product has a built-in real-time clock. In this way, the exact date and time of the last pig passing and the total number of ball passes can be recorded.

Details -

Pig signaller in production!

EMT make Pig Signaller simpler and more effective: EMT’s range of intrusive pig signallers is detector instruments mounted on pig launchers and receiver stations to confirm the launch or arrival of a pig. They can also be mounted at any location on a pipeline and will detect the passage of all types of pipeline pigs. Our intrusive Pig Signaller uses a unique magnetic system to prevent fluid exchange blocked, therefore, it eliminates the risk of leakage from the action seal, also the trigger of the instrument is enhanced flexibility, reduces maintenance costs, and is easy to install to pipelines.

Details -

EMT Customized High Pressure Retrieval Tools!

Removal Tool usually works with Corrosion coupons. Corrosion coupons are necessary equipment to detect or evaluate the corrosion status of the pipeline system. It can accurately display the corrosion situation inside the pipeline system and assist in the maintenance of the pipeline.

Details -

The pig signallers are finished!

Quantity required by customer :44 sets Destination: Indonesia

Details -

Pressure-removable pig indicator with DBB valve!

Removable Pig Signaller used in pipeline pigging operations are generally installed on the incoming and outgoing pipelines of long-distance pipelines. After long-term use, the ball indicator will have equipment corrosion and aging of the rubber seal ring of the movement. This will lead to different degrees of oil and gas leakage, indicator action failure, and other faults. The current solution is to shut down the pipeline. The operator will relieve and empty the oil and gas in the pipeline. And then repairing and replacing the indicator movement.

Details